Capacitance Level Switches

HOW DO CAPACITANCE LEVEL SWITCHES WORK?

Capacitance level measurement is a contact method of level measurement. Capacitance is the ability to store and release electrical energy. Although most objects can do this to some degree, capacitors, consisting of two conducting plates separated by an electrical insulating material called a dielectric, are designed to store large amounts of electrical energy.

Capacitance level sensors work on the principal that some materials hold more electrical charge than others eg) water holds more charge than air. The material is referred to as the dielectric material.

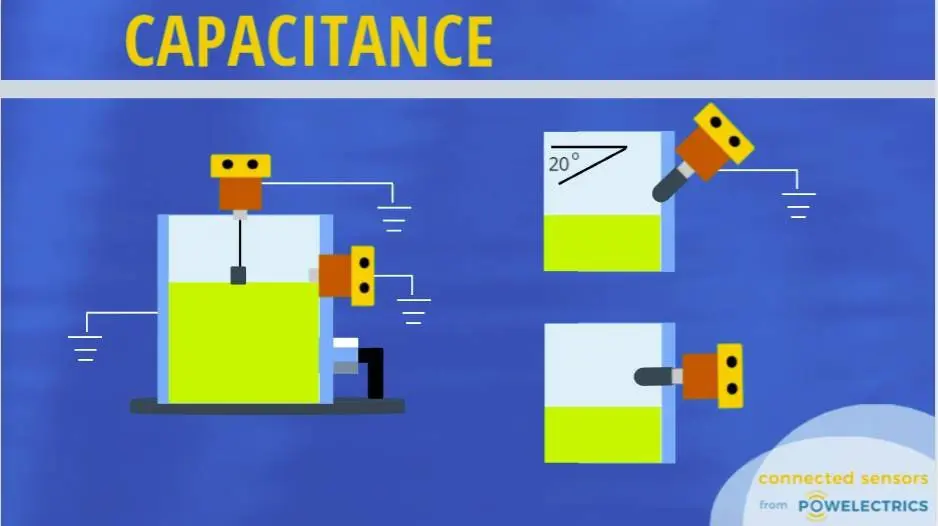

The capacitor in a tank level scenario is created by the sensor in the tank and the wall of the tank. The sensor and the tank wall act as electrodes. The tank contents have a different capacitance to the air in the empty section, so capacitance will change as the tank fills or empties.

WHEN TO USE CAPACITANCE LEVEL SWITCHES

Capacitance sensors are normally used as a point level switch. As product surrounds the sensor then the capacitance changes and the sensor detect this change.

Capacitance sensors are used in a wide variety of industries globally, from liquid level detection in tanks and silos to granular solids, slurries and powder.

Temperature, moisture content, humidity and density all impact capacitance, so capacitance level sensors are not recommended for environments where these fluctuate. Capacitance sensors are suitable for constant high temperatures and pressure applications and often used in hydroponics and machine tools applications.

Capacitance level measurement is not suitable for materials which do not hold much charge.

Capacitive level switches are available for gases to -200 °C as well as hot glue up to +230 °C.

PTFE and PEEK are the preferred materials because they prevent the product from adhering to the sensor and therefore reduce product build up.

THE BENEFITS OF USING CAPACITANCE LEVEL SWITCHES

Capacitance sensors have no moving parts and are therefore mechanically simple and require minimal maintenance, making them highly reliable.

They offer great accuracy and they often have no dead zone, so can measure over the entire sensor length.

ATEX certified level switches are available.

To see the EGE Level Sensor brochure, click here.