Ultrasonic Level Sensors

PowTechnology offer you 30 years’ experience in sensing, monitoring and connectivity. We supply sensors from over a hundred quality international manufacturers. Our broad expertise covers flow, level, temperature, pressure, proximity, distance, colour, movement and many more. Within level, we offer advice and supply a range of non-contact technologies including ultrasonic level sensors.

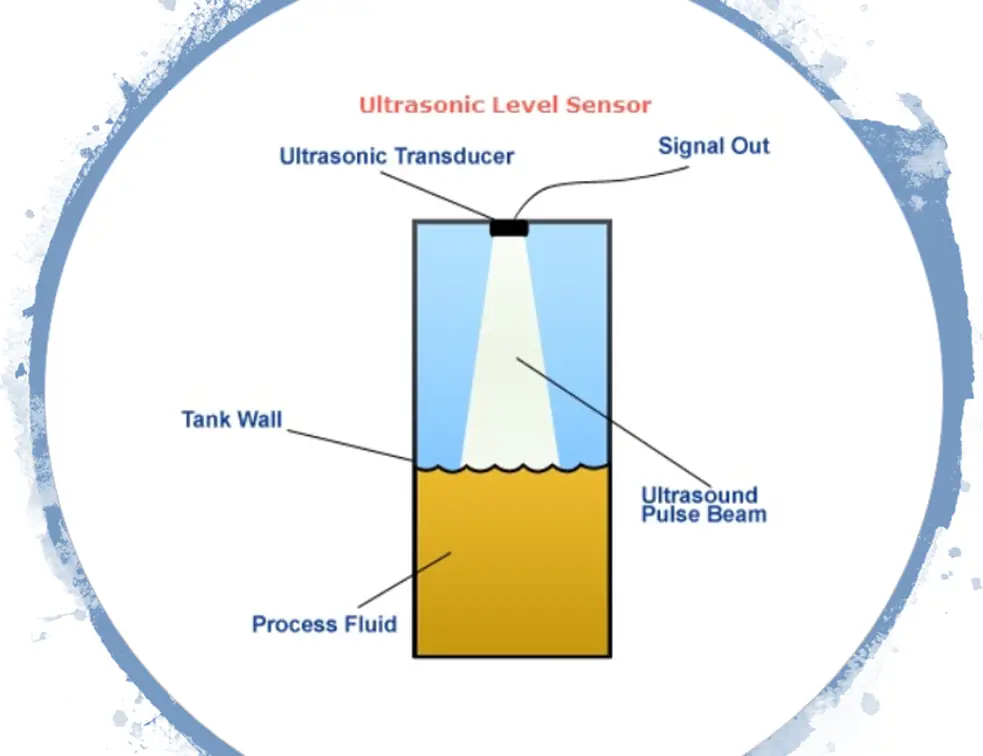

HOW DO ULTRASONIC LEVEL SENSORS WORK?

Ultrasonic level measurement works on the principal of sound waves. When an ultrasonic wave is transmitted and targeted towards an object, it reflects off the surface and the echo is returned to the sender. The time taken for the ultrasonic pulse to travel to the level surface and back reflects the distance it has to travel. By timing this journey, the level can be determined to a high level of accuracy.

WHEN TO USE ULTRASONIC LEVEL SENSORS?

Ultrasonic level transmitters are positioned above the surface, ‘looking’ down. No physical contact is required with the material being measured. Thus, ultrasonic level sensors are well suited to environments where a sensor cannot be simply dropped into the material for hygiene (food, beverage, pharmaceutical), practical (extreme viscosity) or corrosive (acidic, alkaline) reasons.

BENEFITS OF ULTRASONIC LEVEL SENSORS

Whilst more expensive than hydrostatic sensors, ultrasonic level sensors are highly durable and reliable sensors, often used in tanks, wells, channels, or reservoirs.

They have traditionally been more cost-effective than radar technology, although this has changed in recent years.

If your application involves foams, dusts, vapours, uneven surfaces or powders, please see our section on Radar.