Can Digitalisation Drive Productivity AND Sustainability?

PowTechnology have been intelligent automation specialists for over 30 years, enabling clients to improve efficiency, reliability and planning. Thankfully, sustainability is now a central focus for most organisations. Either legislation is forcing compliance or they embrace a corporate social responsibility (CSR) that holds them socially accountable to themselves and their stakeholders.

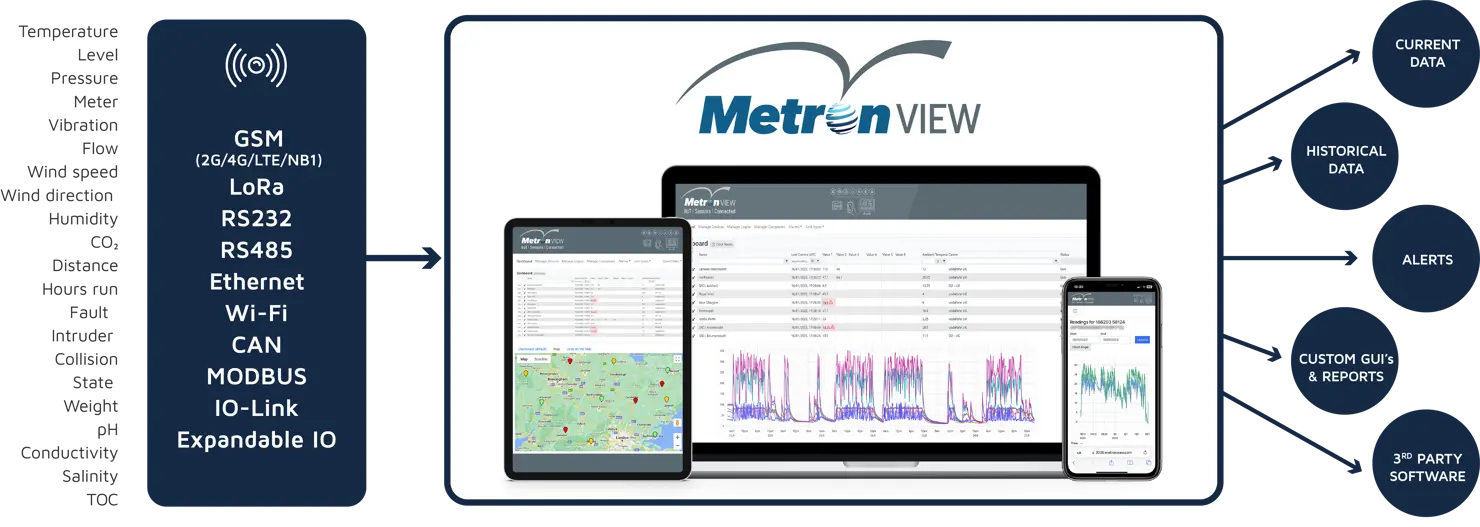

PowTechnology make it easy to connect data from sensors and machines to the cloud, using advanced technology like AI, edge processing and anomaly detection to help businesses improve efficiency, reliability, and sustainability.

This is proven to deliver commercial results, including a 30% reduction in fuel costs, a 12% increase in productivity and a 30% drop in maintenance costs.

We design, manufacture, install and maintain innovative ‘ready-to-go’ and bespoke digital transformation solutions, integrating our own proven IIoT hardware & software with high performance third-party technologies.

Traditional goals in adopting digital transformation have been to improve processes with a view to cutting costs and maximising resource by automating processes, reducing energy consumption, eliminating breakdowns and reducing waste.

Guess what? All of those objectives will also improve sustainability! Digitalisation effectively provides the substance behind sustainability.

Automation has been seen as a way to improve productivity and reduce operational costs since the coal-fired steam engine was invented in 1712.

Condition monitoring & condition-based maintenance are well-proven maintenance management concepts. Manufacturing downtime is expensive! Early failure detection allows planned intervention, avoiding lost production, wasted human resource, squandered overheads, reputational damage, penalties and lost future revenues.

Monitoring production processes, remotely or in-situ and collecting reliable historic and current data provides insight, which allows you to identify ways of improving those processes.

Remote monitoring can also engage multiple stakeholders, achieving a resolution which is compatible with a range of business needs.

Remote monitoring is even more valuable, when the assets or parameters being monitored are geographically dispersed, across a site, a country or a continent. Such assets may not benefit from regular scrutiny … or perhaps the effort of collating that data, means it doesn’t get done regularly, accurately or in time to matter.

GreenChem is a great example of PowTechnology’s remote monitoring kit achieving multiple successes for our customer:

Greenchem, one of Europe’s largest AdBlue® producers and distributors have thousands of contracted customers, supplied from over 40 production facilities around Europe and Brazil.

PowTechnology tank level monitoring is used at customer sites, with data exported via our MetronView cloud to their ERP. The data assists a range of operational activities, primarily logistics planning, helping them schedule many more deliveries with the same fleet and fuel resource.

GreenChem also ensures exceptional service to thousands of customers, who never experience run-outs and remain loyal.

A resounding success for an innovative company wishing to improve productivity, service AND SUSTAINABILITY!

Another super example is Green Biofuels, where the simple retrofit of tank level monitoring on Hydrotreated Vegetable Oil tanks, has enabled centralised logistics to schedule efficient, cost-effective deliveries.

Exceptional customer service has eliminated any run-outs and resulted in a near complete conversion rate of customers to HVO.

Great for growing the business! Great for operating costs! Great for sustainability … even more so as the HVO achieves an 80-90% cut in harmful emissions. An even bigger win for the environment!

PowTechnology offer a wealth of real application cases on our website, demonstrating commercial and sustainability benefits in tandem, from managing effluent and emissions to balancing the needs of reintroduced beavers with those of Scottish landowners. Please click here to learn more.

Many people say that they want to be more sustainable, but either:

- They are put off by the cost of embracing new technology

- They don’t know where to start.

Digital transformation does not cost the Earth … quite the opposite! Virtually every productivity improvement has a beneficial impact on an organisation’s sustainability.

In addition to the traditional benefits of production optimisation discussed above, there is now the increasing weight of compliance and public opinion.

Our daily news is filled with tales of Environment Agency and HSE fines for totally avoidable incidents, such as toxic effluent discharge and spillage.

Add to that the fact that businesses are ‘being cancelled’, or at the very least losing out in tender scoring, for failing to adopt sustainable practices.

Perhaps, you really need to ask yourself: What is the cost of not taking demonstrable action to become more sustainable?

The word ‘sustainable’ is everywhere – present in almost every business event, article and presentation. There is a lot of lip-service! What can you actually do?

Well … you can talk to us! There is no doubt that digitalization drives sustainability, but you don’t need to start with a fully automated smart factory to see the benefits.

Industry 4.0 tech is a great enabler in adopting sustainable practices, but it’s better to make a start than put it off because the project is too daunting or because the initial investment is perceived to be too high to get started.

Here at PowTechnology, we can support you from your first steps into digital transformation through to an international estate of connected assets. Our solutions are highly scalable.

Start simply, see the benefits & scale up. We can show you how the intelligent deployment of IIoT kit, measuring and reporting just a few critical parameters in a process, can have a huge impact.

PowTechnology partners with businesses of all sizes, from start-ups to global multinationals, and our solutions are trusted across a wide range of industries.

We are Siemens Solution Partners, customising Siemens Measurement Instrumentation into holistic, customer-specific, digital transformation solutions.

As an ISO9001/ISO27001 certified company, quality and security are at the heart of everything we do.

Our web site showcases over 30 cases studies, where our technology has been proven to deliver the benefits described above.

PowTechnology welcome your enquiries. Please come to us with your application ideas and we will do our very best to help!